Mr. Tatsuo Umehara, a third-generation potter of the Hokuryu Kiln upholding traditional handmade methods of teapot-making.

Mr. Tatsuo Umehara, a third-generation potter of the Hokuryu Kiln upholding traditional handmade methods of teapot-making.

He shared the appeal of Hokuryu Kiln teapots with us while showing us the teapot-making process.

Spiral-patterned spouts

To enjoy delicious tea, various ingenious mechanisms are added to teapots but characteristic of pottery made on a potter’s wheel is the creation of a spout’s parts. When a spout is made on a wheel, a spiral pattern remains inside the spout. With this pattern, tea does not flow in a straight line when it is poured – the tea comes out in a spiral so it is possible to pour tea slowly.

This spiral pattern cannot be made utilizing a molding technique so even potters who are skilled at making pottery using molds use the potter’s wheel to create this part of a teapot.

Mr. Umehara showed us a cross-section of a spout that he made.

Mr. Umehara showed us a cross-section of a spout that he made.

Achieving a thinness that feels natural to the touch

We were also shown the inside of a teapot. The thinnest part is 3 to 4 millimeters, but the strength of the upper part that supports the lid and the bottom part were enhanced with a thickness strong enough to resist cracking.

We were also shown the inside of a teapot. The thinnest part is 3 to 4 millimeters, but the strength of the upper part that supports the lid and the bottom part were enhanced with a thickness strong enough to resist cracking.

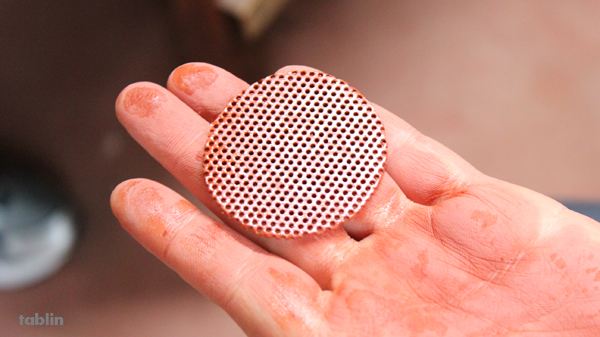

Mesh-like tea strainers made out of clay

The inventor got the idea for a mesh-like strainer made out of clay after seeing the small round holes in a radio’s speaker. After holes are made in clay using a dedicated machine, the clay is rounded and shaped into a strainer. Because these strainers are made out of clay, they are more durable than stainless steel ones. They are made in a way that allows for extremely easy pouring so these strainers are used in many Tokoname ware teapots.

The inventor got the idea for a mesh-like strainer made out of clay after seeing the small round holes in a radio’s speaker. After holes are made in clay using a dedicated machine, the clay is rounded and shaped into a strainer. Because these strainers are made out of clay, they are more durable than stainless steel ones. They are made in a way that allows for extremely easy pouring so these strainers are used in many Tokoname ware teapots.

Here is an actual demonstration of a large-sized teapot being made on a wheel.

This teapot was made not for display, but for actual use. Mr. Umehara was commissioned to create a teapot for use in large tea ceremonies and can hold tea for about 20 people at a time. To create such a teapot requires a craftsman with more advanced skills.

The Hokuryu Kiln makes its own clay.

The raw material of their clay is a type of soil that produces reddish-brown pottery. It looks like grey rocks but once it is fired, its color turns to red. (The clay that is thrown on the wheel is red because it has been blended with “bengara” or iron oxide gathered from soil.)

The Hokuryu Kiln crafts numerous, very beautiful teapots but they continue to make improvements in the pursuit of ease of use and durability.

Third-generation Mr. Tatsuo Umehara of the Hokuryu Kiln crafts teapots with ingenuity all around.

– 2014/10/25Posted in: ceramic artist, Japanese tablin news, traditional craft