Commissioned by a knife smith, the grinding and polishing of a knife is the job of a craftsman who produces the edge of a blade. Many Sakai knives are produced through division of labor, and craftsmen specializing in skills such as knife smithery, producing the edge of a blade and handle-making utilize traditional techniques to create a supreme knife.

Commissioned by a knife smith, the grinding and polishing of a knife is the job of a craftsman who produces the edge of a blade. Many Sakai knives are produced through division of labor, and craftsmen specializing in skills such as knife smithery, producing the edge of a blade and handle-making utilize traditional techniques to create a supreme knife.

Producing a blade by grinding

Sharpening during producing the edge of a blade utilizes various tools such as rough whetstone, semi-rough whetstone and whetstone for the final sharpening. In order to turn a knife-shaped lump of iron into a blade, the first step of producing the edge of a blade involves grinding instead of sharpening.

A wooden rod (sharpening rod) made to fit the shape of a knife is affixed to the knife. Using a whetstone that rotates at a very high speed, the edge of the knife is produced and its shape is formed by sharpening it repeatedly.

It’s not just about sharpening.

Knives should not have bent or distorted places. A craftsman who produces the edge of a blade can feel the slightest distortion and takes it out. Distortions are fixed by finely re-hammering the blade. If there is even a slight distortion, sharpening the blade will be difficult so by “interacting” with the knife, it is formed into an ideal shape.

“Urasuki” (curved shape)

“Urasuki” (curved shape)

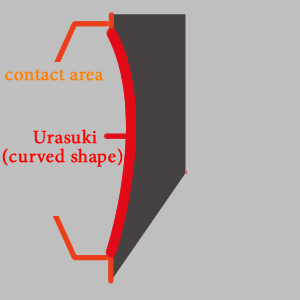

Knives are structured in various ways but with regard to Japanese knives which are single-edged, their rear parts are formed to have slightly curved surfaces called “urasuki.” The curved surface reduces frictional resistance when cutting ingredients so that they would not easily stick to the knife, and it also creates sharpness.

In addition, urasuki is created by a craftsman because during re-sharpening of the rear surface, the parts that hit the whetstone become small surfaces therefore the knife can be sharpened for just a few number of times, facilitating the knife’s maintenance.

Wooden type whetstone

Wooden type whetstone

The wood in a rotating whetstone made of Japanese cedar produces a beautiful sheen on a knife. This process of using a rotating wooden whetstone is a traditional technique characteristic of Sakai knives.

After completing other various sharpening processes, the edge of a blade is finished.

With a superior sharpness that appeals to the world and with beautiful patterns such as those found in Japanese swords, each knife is carefully made by sharpening craftsmen.

Mr. Norikatsu Nishimura, a veteran craftsman who has produced blade edges for over 50 years.

Mr. Norikatsu Nishimura, a veteran craftsman who has produced blade edges for over 50 years.

Mr. Nishimura who kindly agreed to be featured here produces blade edges and has been officially recognized as a traditional craftsman.

I had my own kitchen knife fixed because it was nicked in places. Please watch the video of the knife being fixed. The knife’s sharpness was impressively revived.

Mr. Norikatsu Nishimura, a craftsman who makes the edge of a knife’s blade with superior sharpness and beauty. Sakai Takayuki

– 2014/11/17Posted in: Japanese tablin news, traditional craft